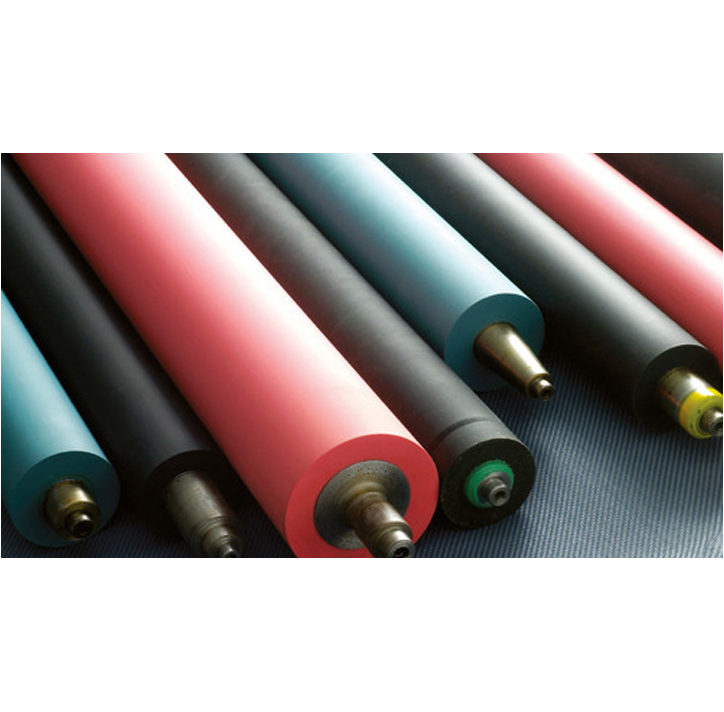

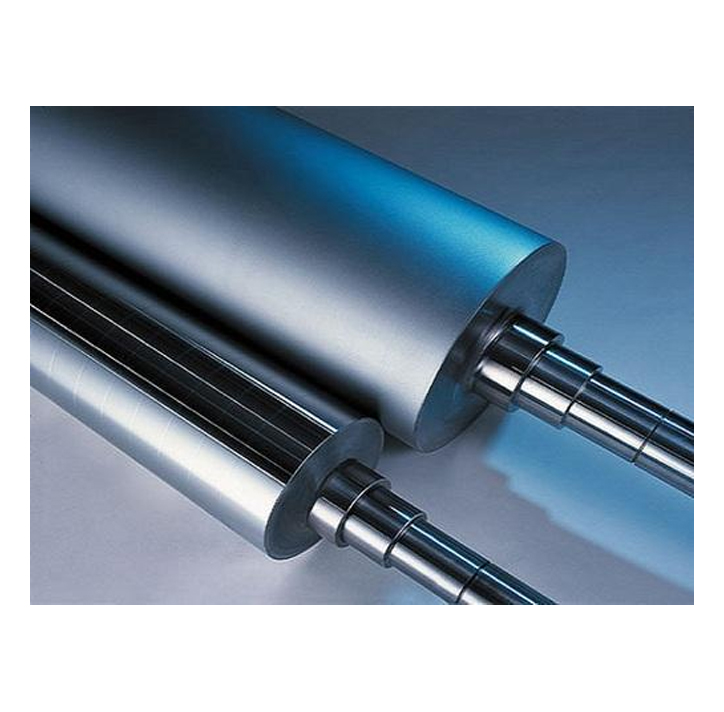

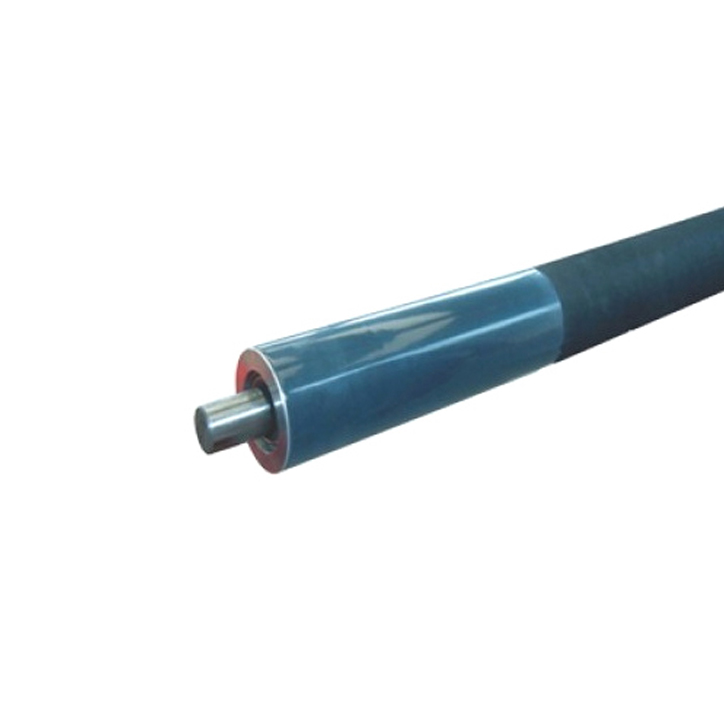

Rolls are the main and very costly consumables in a rolling mill. They are used to roll steel in the rolling mill and their performance depend on many factors which include the materials used and the loads to which they are subjected to during service. The roll design is influenced by the limitations applied by the rolling load, the roll strength and the torque available for rolling. In case of flat rolling it is also influenced by the allowance made for roll bending and by cambering of the rolls. The roll design is to take care the load and torque required for any pass. In addition it must ensure that the physical dimensions and material of the roll are capable of with standing the heaviest loads arising during the rolling sequence. Another important factor where roll life is concerned is the wear properties of the roll material.

Plot no 113 Bharat Compound Raju beads landmark

Masoom Hospital , Bhiwandi Dist. Thane, Maharashtra

Pin code : 421302

Phone – +91 7903306938

E-mail – info@fi-way.com